The automatic slack adjuster (ASA) can generally be retrofitted to older vehicles that currently use manual slack adjusters. However, there are several considerations to ensure a successful retrofit:

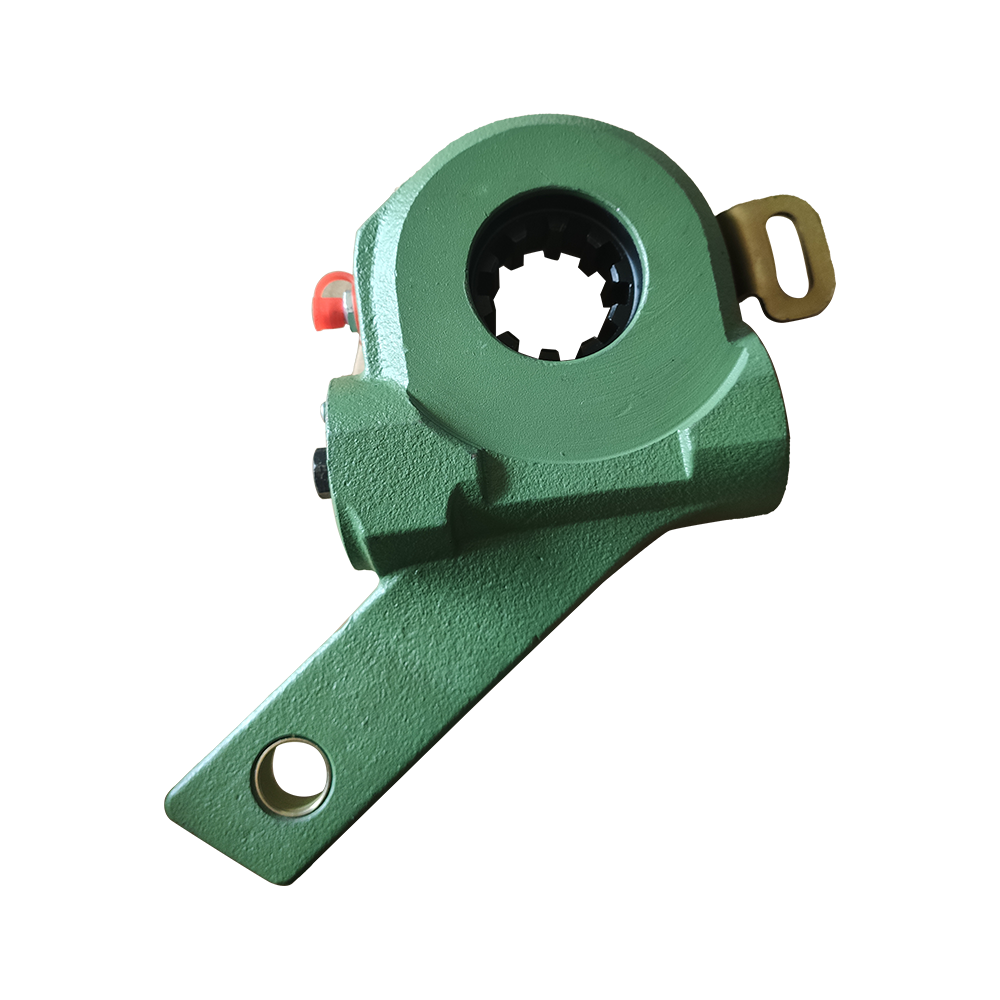

Compatibility: Compatibility is the cornerstone of any successful retrofit. When considering retrofitting an ASA to an older vehicle with manual slack adjusters, it’s essential to conduct a thorough compatibility check. This involves examining the physical dimensions of the ASA, such as the arm length, which must match the existing brake system’s geometry to avoid any installation issues. The spline size, which refers to the number and shape of the grooves on the ASA's mounting shaft, must also correspond with the vehicle’s brake camshaft.The mounting configurations, including the angle and position of the mounting holes, need to be aligned with the vehicle’s brake chamber to ensure a secure fit. Verifying these compatibility aspects ensures that the ASA will integrate seamlessly with the vehicle’s brake system, preventing potential operational issues and ensuring brake performance.

Vehicle Specifications: Each vehicle’s brake system is designed with specific performance criteria, such as brake force requirements and stroke lengths, which must be met for safe operation. The ASA must be capable of delivering the required brake force, which is the amount of pressure applied to the brake drum or disc to slow down or stop the vehicle. The ASA must operate within the brake system’s stroke length, which is the distance the brake pushrod travels to engage the brakes. Ensuring that the ASA can handle these specifications is crucial to maintaining the vehicle’s braking efficiency and safety. Failure to match these specifications can result in inadequate braking power or excessive wear on the brake components.

Installation: Installing an ASA is more complex than simply replacing a manual slack adjuster. The process begins with the removal of the old manual slack adjuster, which may involve loosening and detaching it from the brake camshaft and brake chamber. This step often requires specialized tools and a clear understanding of the brake system's layout. The ASA is then installed by securing it to the brake camshaft and ensuring it is correctly aligned with the brake chamber. Correct installation also involves setting the initial tension and ensuring that the ASA's adjustment mechanism is functioning properly from the start.

Adjustment: Once installed, the ASA needs to be properly adjusted to ensure it maintains the correct brake shoe-to-drum clearance. This initial adjustment is crucial as it sets the foundation for the ASA's automatic adjustment capabilities. An incorrect initial adjustment can bring about excessive wear or insufficient braking force. The ASA's mechanism will then maintain this clearance automatically, compensating for brake lining wear over time, which reduces the need for frequent manual adjustments and ensures consistent braking performance.

Maintenance: Although ASAs significantly reduce the frequency of manual adjustments, they still require regular maintenance to ensure they continue to function correctly. Maintenance includes routine inspections to check for signs of wear, damage, or corrosion. Regular lubrication of moving parts is also necessary to prevent friction and ensure smooth operation. Technicians should verify that the ASA's adjustment mechanism is working properly and that there are no blockages or debris that could impair its function. Regular maintenance helps to extend the lifespan of the ASA, ensures reliable brake performance, and prevents unexpected brake failures.

Haldex 72779 AA1 korea truck automatic slack adjuster replaces fit in daewoo bus

English

English русский

русский Español

Español Deutsch

Deutsch

.png?imageView2/2/format/jp2)

-1.png?imageView2/2/format/jp2)

.png?imageView2/2/format/jp2)

-1.png?imageView2/2/format/jp2)

-1.png?imageView2/2/format/jp2)

-1.png?imageView2/2/format/jp2)